Deciding which gantry crane to buy isn’t easy. There are many considerations and options. Wallace cranes, for example, has over 200 different gantry crane makes and models to choose from ranging in size from 4 to 24 feet in height and with lifting capacities from 1/2 to 15 tons.

To guide you in making the most beneficial and cost-effective choice for your business and application, we have created this document to spell out the different things you need to know and reflect upon before making your final decision.

It helps to have an overview of your options before you start. Choosing the right crane helps mitigate the risk of accidents and property damage. It can save your company time and money and improves its reputation as a safe and desireable workplace.

Wallace Gantry Product Line

Wallace Cranes offers hundreds of different gantry cranes and works with major hoist vendors to provide a broad range of lift equipment accessories so you can have a guaranteed fit. If “standard” does not work, we have an equally broad range of custom and semi-custom options.

Wallace gantry cranes come in six different models. The difference between models has to do with:

A brief description of each of the models is provided below. While Wallace can easily modify many of the “standard” models, some parameters cannot be changed. For example, the span and the desired load lock in a given I-beam section. And while caster frames can be “adjusted”, the amount of adjustment is limited by the requirement to keep the crane stable both statically and while rolling.

- Steel or Aluminum

- Fixed Height or Adjustable Height

- 1/2 to 7 1/2 Ton Capacity

- Spans up to 35 feet (lower heights and shorter spans in Aluminum)

- Heights from 6′ 7″ to 18′ 4″

- Fixed Height Steel

- 1 to 5 Ton Capacity

- Spans 10 to 35 Feet

- Heights: Nominal 10, 13 or 16 Feet

- Steel

- Fixed Height

- 500 to 1000 Pound Capacity

- Spans from 8 to 15 Feet

- Heights from 5′ 3″ to 12′ 0″

- Steel

- Fixed Height

- 15 Ton Capacity

- Heights from 15′ 1″ to 23′ 10″

- Spans from 15 to 35 feet

- Wallace will customize any crane

to fit your needs - Fixed and Adjustable Height

- 1/4 to 15 Ton Capacity

- Spans 8 (or less) to 35 Feet

- Heights: 4’2″ (or less) to 23’10”

Terminology

Next, there is a lot of specialized terminology when it comes to gantry cranes. We have defined the terms you will need to know in order to be able to narrow down your options.

-

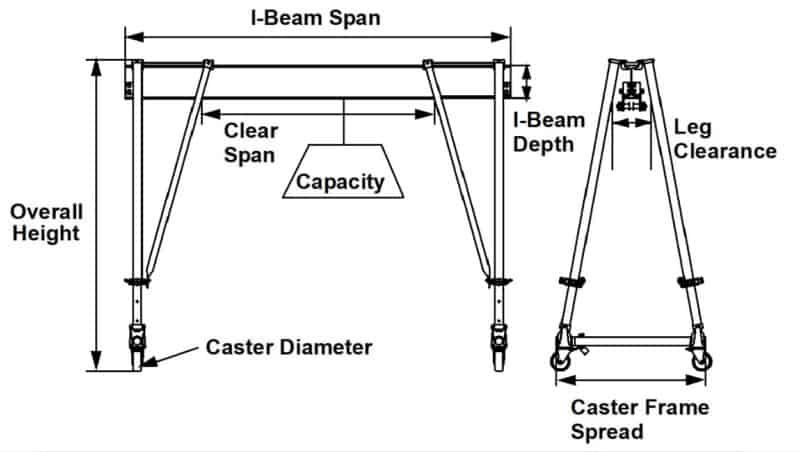

- Capacity – The amount of weight the crane is designed to carry.

- Caster Diameter – Outside Diameter (OD) of the caster (ranges from 6” to 12” depending on load rating).

- Caster Frame Spread – The size of the “base” on the crane.

- Clear Span – Distance between brace legs (if present).

- I-Beam Depth – Height of the I-Beam, ranges between 4” and 24”, dependent on Span and Capacity.

- I-Beam Span – Overall Length of the I-beam. While most charts show 5-foot increments, I-beams can be cut to fit.

- Leg Clearance – Distance between the legs at the bottom of the I-beam. This tells you if a hoist can fit through the legs.

- Overall Height – Height of the crane from the floor to the highest point.

While not a complete list, knowledge of these basic parameters will help you address the issues in getting a crane to fit your particular needs.

While Wallace offers hundreds of standard cranes (fixed height and adjustable) and can modify many of the “standard” models, some parameters cannot be changed. For example, the span and the desired load lock in a given I-beam section. And while caster frames can be “adjusted”, the amount of adjustment is limited by the requirement to keep the crane stable both statically and while rolling.

Questions To Ask Yourself

To start to narrow your options, it’s best to think through your answers to four questions:

-

- How heavy is the load you want to lift?

- How high do you want to lift the load?

- How wide does the crane have to be to span the load?

- Are there any special location, environmental, or power needs?

1. How Heavy is the Load?

The weight of the load you want to lift will determine the maximum lifting capacity of the crane models you can choose from. Wallace has models with capacities ranging from one-quarter to 15 tons.

2. How High do You Have to Lift the Load?

You should bear in mind whether the load will have to be lifted over equipment on the shop floor or whether there are any overhead obstructions or ceiling restrictions as this will also reduce the amount of space you have available to lift a load. The crane itself has parts and pieces that will have to be factored into your calculations.

Stacking

Stacking is an important consideration when deciding how high you have to lift the load. Stacking includes everything underneath the I-beam that effectively reduces its lifting height potential. Stacking includes the space needed for the following parts:

Trolley

Hoist

Spreader Beam

It is imperative to understand that a hoist must be suspended with a hoist/trolley combination or at least a beam clamp. You should never attach a hoist to the I-beam with a sling. Slings are frequently used to pick up both bulk materials and delicate or oddly-shaped objects. While convenient, slings can add substantially to the “headroom” and thereby reduce the amount of space you have available to lift a load.

This image clearly shows that sling height is close to the headroom of most hoists, so make sure you are factoring that in when you are deciding on the height of your crane.

Headroom Basics

-

-

- Hoist Headroom – Hook to Hook Distances

- Hook Height – Distance from the top of the crane to the hook. Subtract this distance from the Overall Crane Height to see if a given crane will “fit.”

- I-Beam Depth – For a given capacity and span, this number cannot be changed.

- Trolley Headroom – Distance from the bottom of the I-beam to the top of the hook.

-

Example: 3-Ton Crane, Typical Sizes

The sketch above shows a “typical” trolley and hoist mounted on a 12” I-beam. As stated before, when you start to consider all the heights for the crane brackets, trolley hook height, I-beam depth, hoist “hook-to-hook,” the amount of available space “below” the hook decreases rapidly. Wallace sales staff can help you choose the correct crane and hoist/trolley combination to meet your lifting requirements.

3. How Wide Does the Crane Have to be to Span the Load?

The need to lift loads over equipment is important when considering the necessary crane width or span. Does the crane has to move over an object or does the object have to move over the crane? If the crane must move over the object, the crane will need to be able to “span” it. The crane span is the length of the i-beam. Wallace cranes typically span 8 to 35 feet.

Clear Span and Brace Legs

Tri-Adjustable, Hippolift, and Mighty Mite cranes all have brace legs. These legs keep the frame rigid while moving, providing additional stability in the line of travel parallel to the I-beam.

The clear span is the distance between brace legs.

4. Are There Any Special Location, Environmental, or Power Needs?

Location

Before buying, make sure the location is suitable for the crane.

Wallace Cranes are designed to move on smooth flat, concrete surfaces. While the proprietary four-bar linkage ensures the casters are all on the floor, you should avoid moving the crane over obstructions and debris.

There are a few cautions to be noted about the concrete flooring. Because of the loading of the crane transmitted to the floor through the casters (essentially a “line load”), the flooring beneath a crane should be 3,000 psi (pound-force per square inch) concrete at least 18” deep with one or more courses of rebar. The standard Wallace casters, in either phenolic or steel core with polyurethane tread, are fully capable of smoothly running the crane across the floor at full load.

An option is to have the crane track mounted. For these cranes, typically with an electric motor drive, the casters are replaced with V-groove steel, running on a track (angle iron mounted on a plate). Wallace builds this track in-house with three different capacities, 1-5 tons, 8-10 tons, and 15 tons. The track sections are available in standard 5 and 10-ft lengths, with male and female sections for smooth running. The track is held in place with a Wallace Track Clip (a cast iron part) bolted to the high strength concrete floor. Wallace also makes track with end stops and a removable transition section for high traffic areas.

Cleanroom and Harsh Environments

Working with the hoist vendors, Wallace can provide “food-grade” hoists and trolleys for either clean-room or harsh environments (chemical or outdoors). However, in many cases, standard grade equipment (available at far lower cost) is used instead of the costly stainless-steel equipment with stainless-steel chains. You can often get several years of life even in adverse conditions.

One of the ironies is that a crane for use in a cleanroom is frequently used in wastewater treatment. In a clean room, the unpainted aluminum I-beam typically does not “shed” particulate matter. And the lubricants used in the hoist (and the hoist chains), trolley, and casters have minimal outgassing.

Because of the use of corrosives like chlorine compounds or the need to run the cranes outside, aluminum is often preferred for both lightweight and weather resistance. Lightweight is often a key consideration as our cranes are frequently shuffled between sites or within a single site where there are no continuous paths between various tanks or pump locations.

Power Needs

Will the hoist and trolley be manual or electric? If the hoist is electric, what is the required voltage? Higher capacity hoists, greater than 2 tons, generally require 3-phase electricity.

Conclusion

Please let us know if you’d like to request a quote for a gantry crane. We also sell lifting tripods, forklift boom attachments (Liftruks), jib cranes, and crane accessories.

For more information about gantry crane standards, regulations, and guidelines, please consider the following:

- American National Standard Institute (ANSI): http://ansi.org/

- American Society of Mechanical Engineers (ASME): https://www.asme.org/

- Occupational Safety & Health Administration (OSHA): https://www.osha.gov/.

Contact us (610-647-1400) if you’d like additional information about any of our products and services. We would be more than happy to assist you.